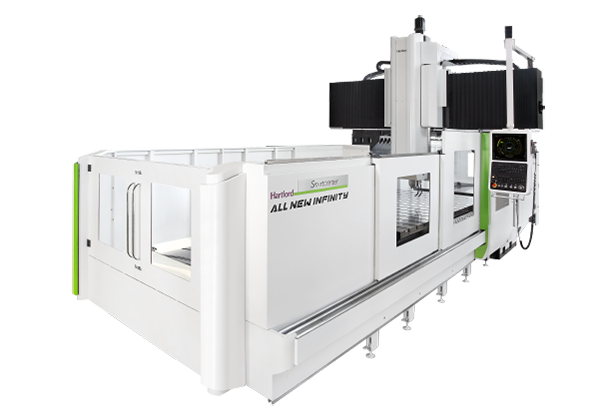

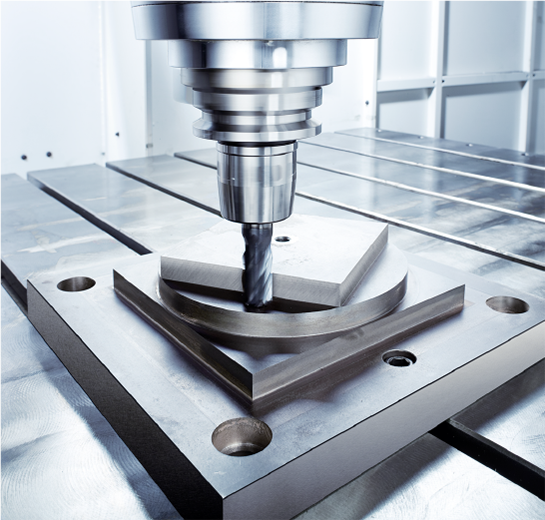

HSA series = high rigidity + high-precision

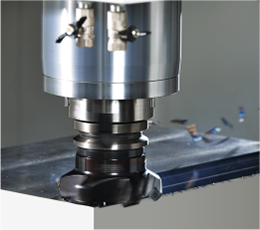

Fantastic performance for any machining application

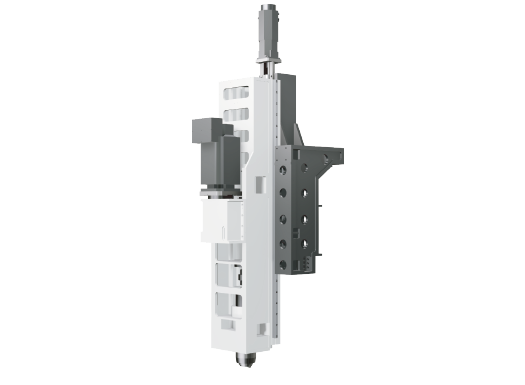

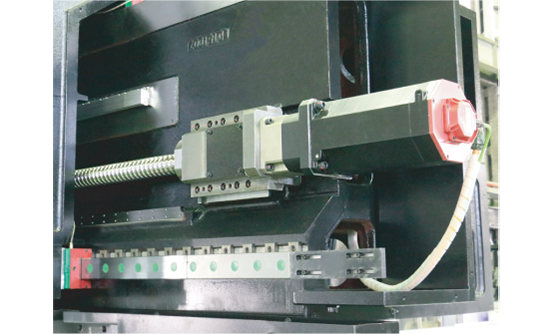

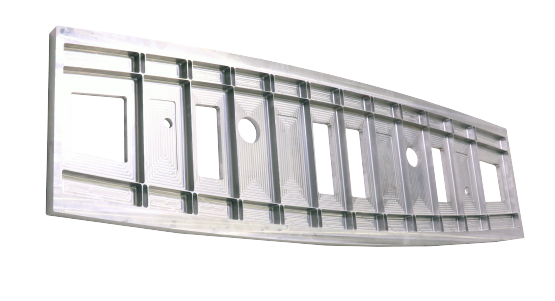

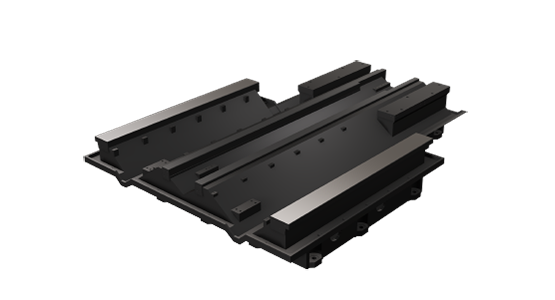

1. Z-axis four linear guideways three binding structure patented technology, two-way support provides 20% rigidity while cutting, bring you excellent performance.

2. Multiple choice of spindle , ex. DDS, gear head 8000 rpm

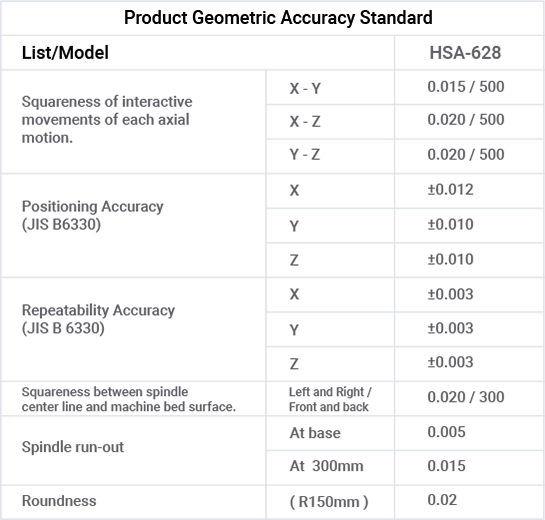

3. Self-made spindle, deflection within 5μm.