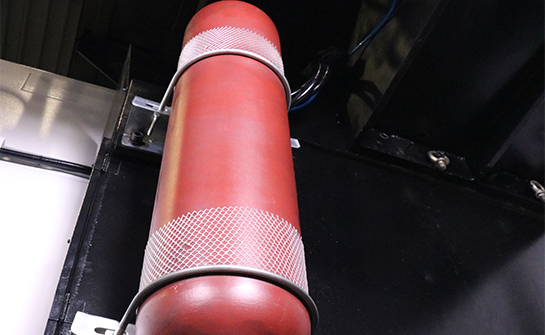

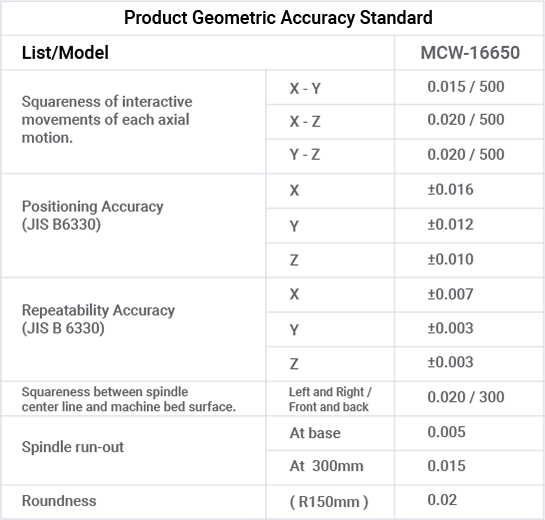

Self-made Hybrid type 10,000 spindle

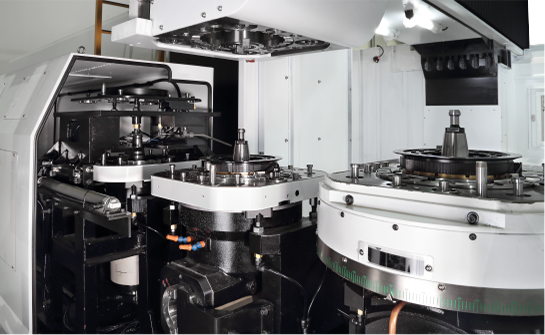

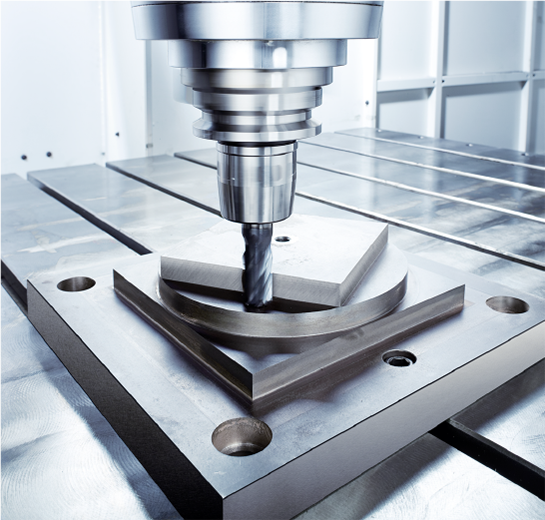

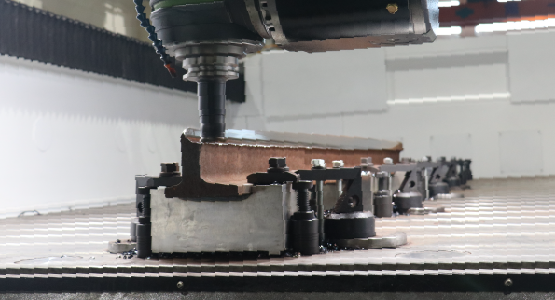

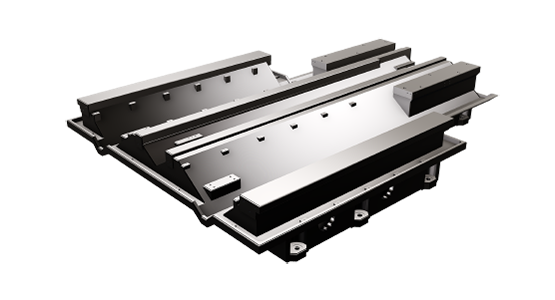

MCW Series = High Rigidity + High Precision

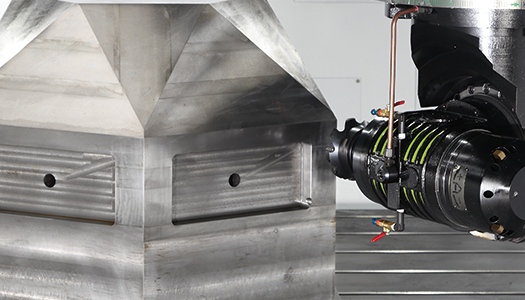

Fantastic performance for various machining application

1. Z-axis four linear guideways three binding structure patented technology, two-way support provides 20% rigidity while cutting, bring you excellent performance.

2. Multiple choices of spindle: self-made gear head 8000 rpm, i-Tech hybrid 10000 rpm spindle design.

3. High quality self-made spindle to ensure spindle run-out within 5μm.

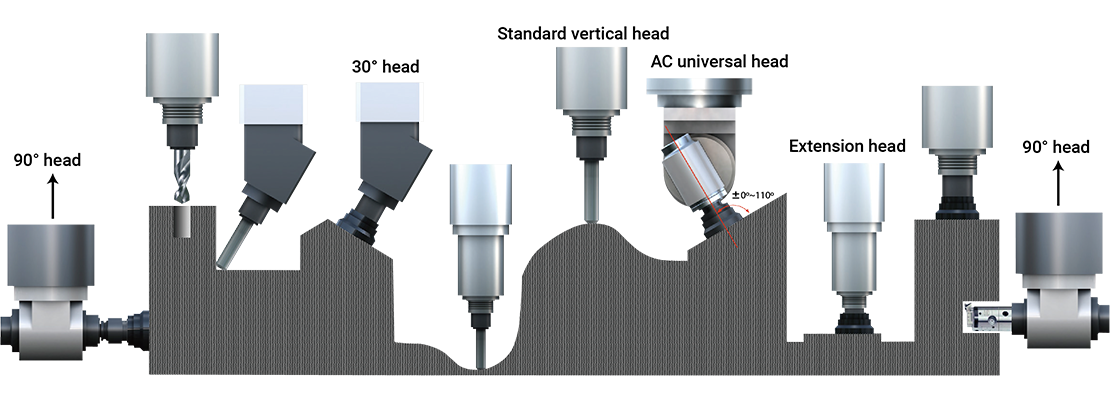

4. Comprehensive automatic angular head options to meet the diverse machining needs: A/C axis indexing 1 degree.