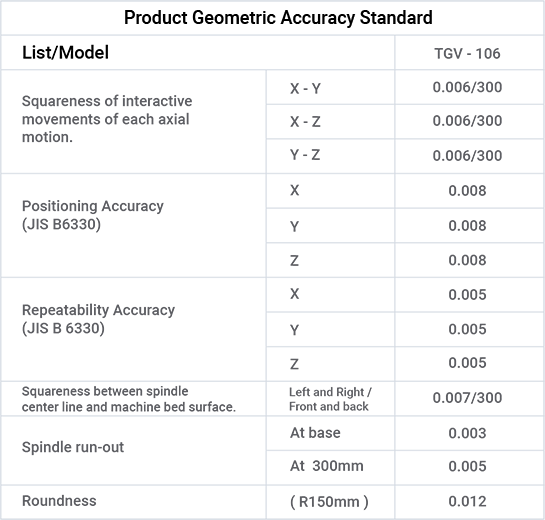

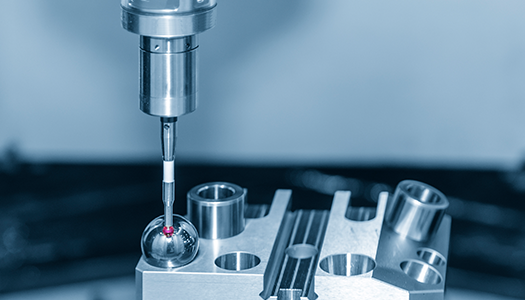

MGPS with positioning accuracy within 8μm , repeatability accuracy within 5μm.

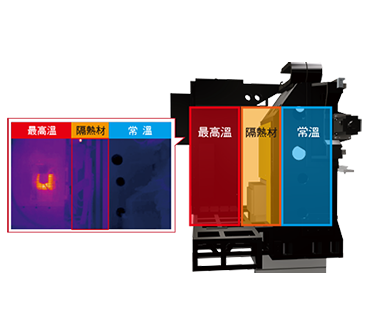

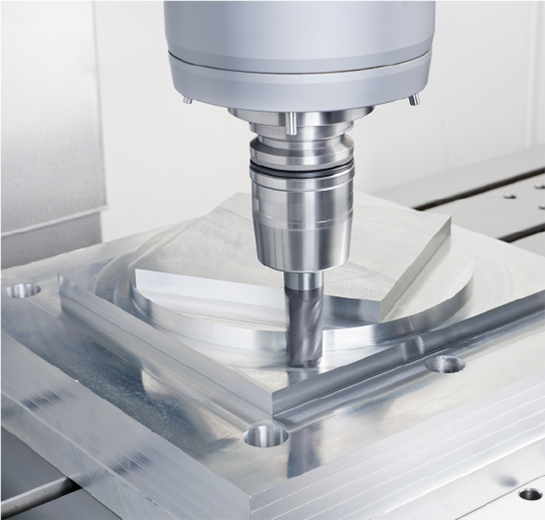

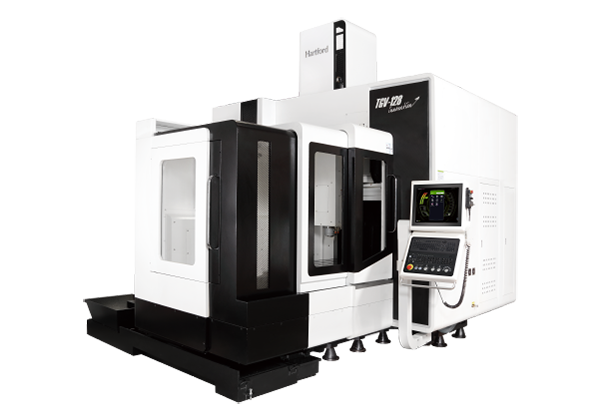

MGPS (Micro-Grade Process and Standard) and High Efficient Spindle

μ-grade accuracy performance, 24hrs spindle operation

1. MGPS ( Micro Grade Process and Standard ) with positioning accuracy within 8μm , repeatability accuracy within 5μm.

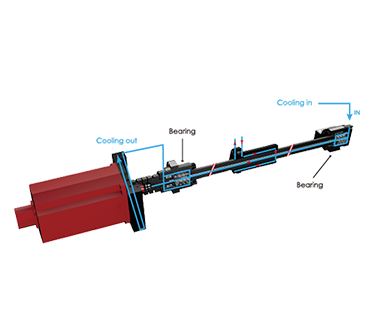

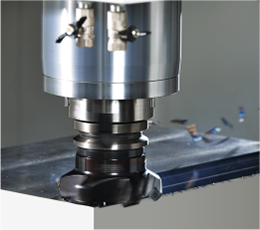

2. High quality self-made spindle to ensure spindle run-out within 5μm.

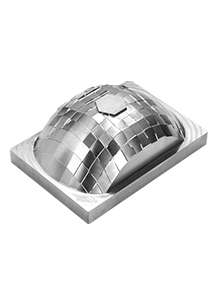

3. Oil-air lubrication spindle:Spindle bearing is lubricated by lubrication oil, spindle is capable of long term running.

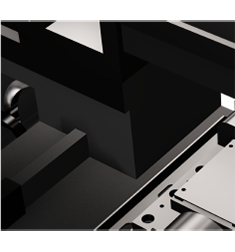

4. Two face binding design for increasing cutting capability and machining accuracy, accuracy raised 30%.