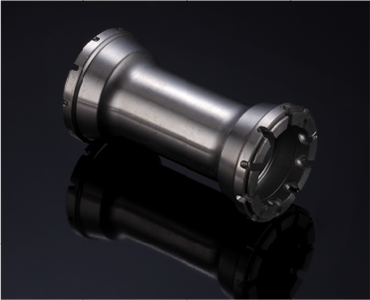

MGPS (Micro-Grade Process and Standard) and High Efficient Spindle

μ-grade accuracy performance, 24hrs spindle operation

Logout?

Log Out

Are you sure to log out ?

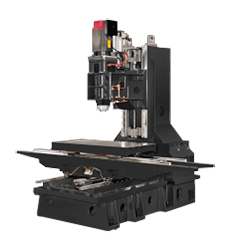

Vertical Machining Center (Linear guide way)

Highly-Efficient AI Vertical Machining Center

Highly-efficient Performance

One & only :

Accuracy is not affected by environmental factors due to AI Tech application. Efficiency of machining is enhanced as factory ambient temperature remains constantly, and not affected by workpiece weight and the wear of tools. Thanks to automatic operation function, which it is similar to autopilot of Tesla.

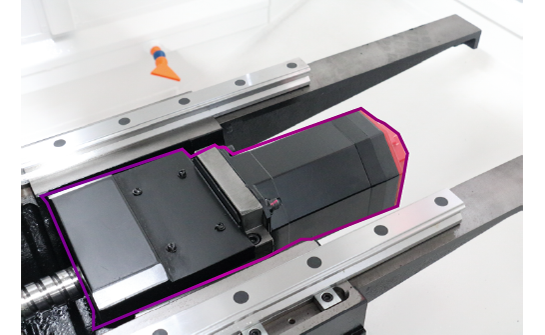

Full range of linear guide way 5 years warranty

One-piece bed design

1. High accuracy linear guide way:Provides high accuracy and high stability for heavy cutting.

2. Z axis without counterweight provides the best dynamic accuracy.

3. High rigidity design:Enhance structure rigidity and stability, prevent twisting and distortion under even the most severe cutting force.

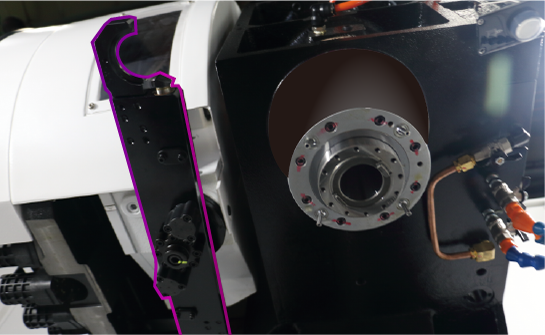

Direct driver servo motor coupled with ballscrews

Excellent tool change time

1. 3-axis direct direct drive transmission between servo motor and ballscrews: High torque servo motors are directly coupled with ballscrews, without backlash or servo lag problem caused by belt.

2. Excellent tool change time:Minimum tool change time is 1.38 secs.

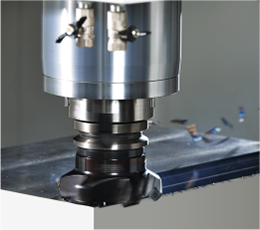

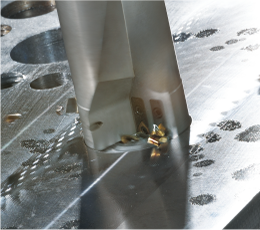

Face milling

End milling

Tapping

Drilling

1. Decades of machine tool manufacturing technology, plus new developed AI technology, makes the machining accuracy/efficiency/finish almost equal to the level of Japanese machines

2. “Super Speed Cycle time” makes cutting efficiency 15% ~ 50% higher than Taiwanese peers

.Model:S PLUS-10

.Spindle:DDS 10,000 rpm 11 kW

.Cutting material:S 45C

Tolerance of 3D contouring accuracy conforms to the standard:

Result of 114 spots test is approved within tolerance (± 0.02mm).

OMV (On Machine Verification): 3D Inspection is directly employed based on OMV system, which ensures each workpiece is qualified, and efficiency is enhanced to reduce time on workpiece upload/load on the table.

Worktable size

1150x520

mm

Max. load (Average)

700

kg

T-slot Width x pitch (number)

18 x 100 (5)

mm

X axis travel

1020

mm

Y axis travel

520

mm

Z axis travel

550

mm

Spindle nose tapper

#40

Spindle speed (Pulley)

8000/10000/12000

rpm

Spindle speed (DDS)

10000/12000/15000

rpm

Capacity

A:24 (30)

pcs

Tool shank

BT40 ( BBT /CAT /DIN )

Spindle drive motor (cont/30min)

7.5 / 11 opt. 11 / 15, 15 /18.5

kw