In the Taichung Industrial Zone, there is a company quietly bringing “Made in Taiwan” onto the global stage.

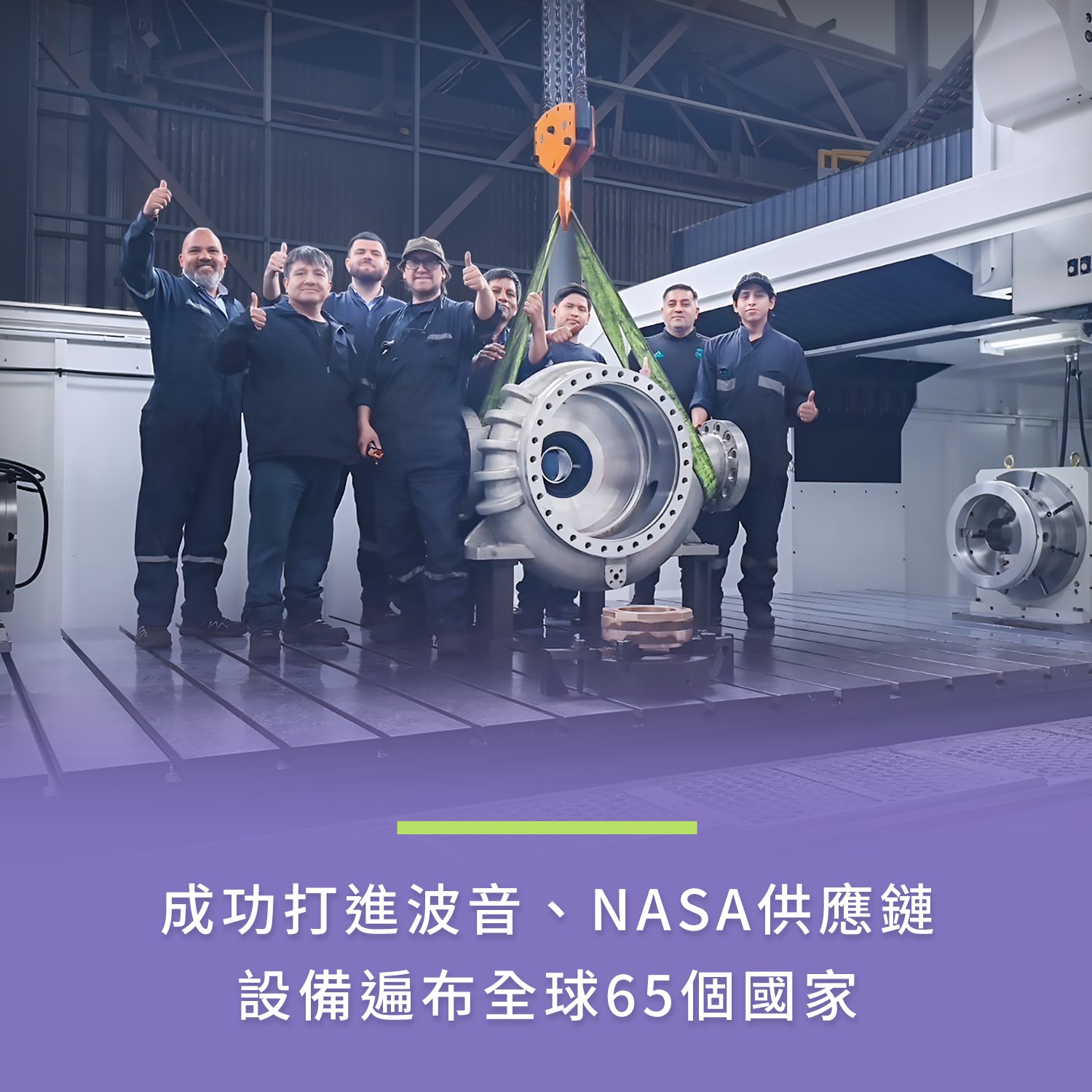

Their precision machinery is running in NASA’s space programs, supporting Boeing’s production lines, with equipment deployed in 65 countries worldwide and more than 30,000 units delivered — making “Made in Taiwan” shine across the globe like the sun that never sets.

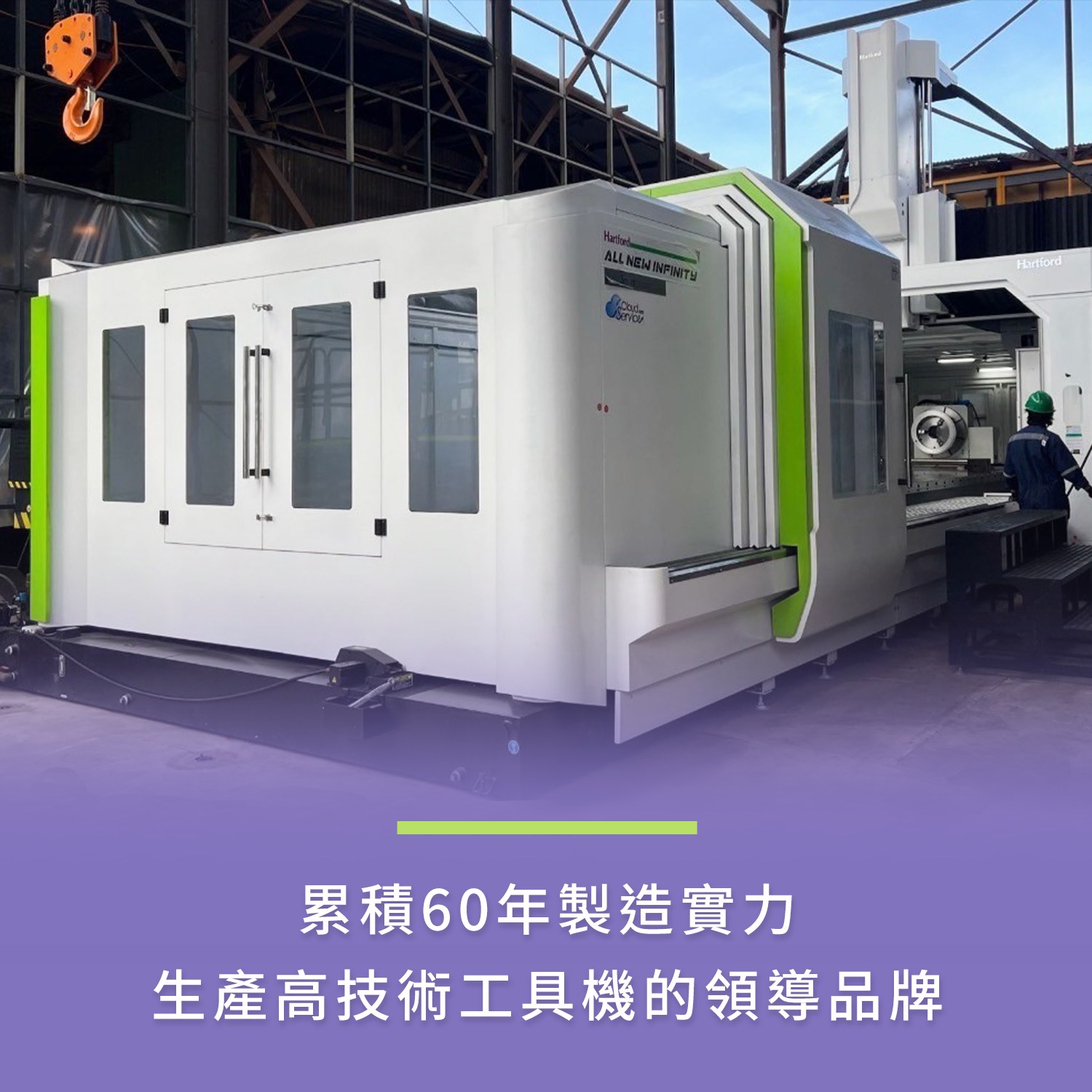

The story began 60 years ago, when a young machinist named Chen Chien-Chih started a business beside a sugarcane field in Taichung. Holding fast to the belief that “we can’t just be an OEM; we must have our own technology,” he worked seven days and nights without sleep to handcraft Taiwan’s first Bridgeport-type milling machine, opening a new chapter in Victor Taichung’s Hartford of independent R&D.

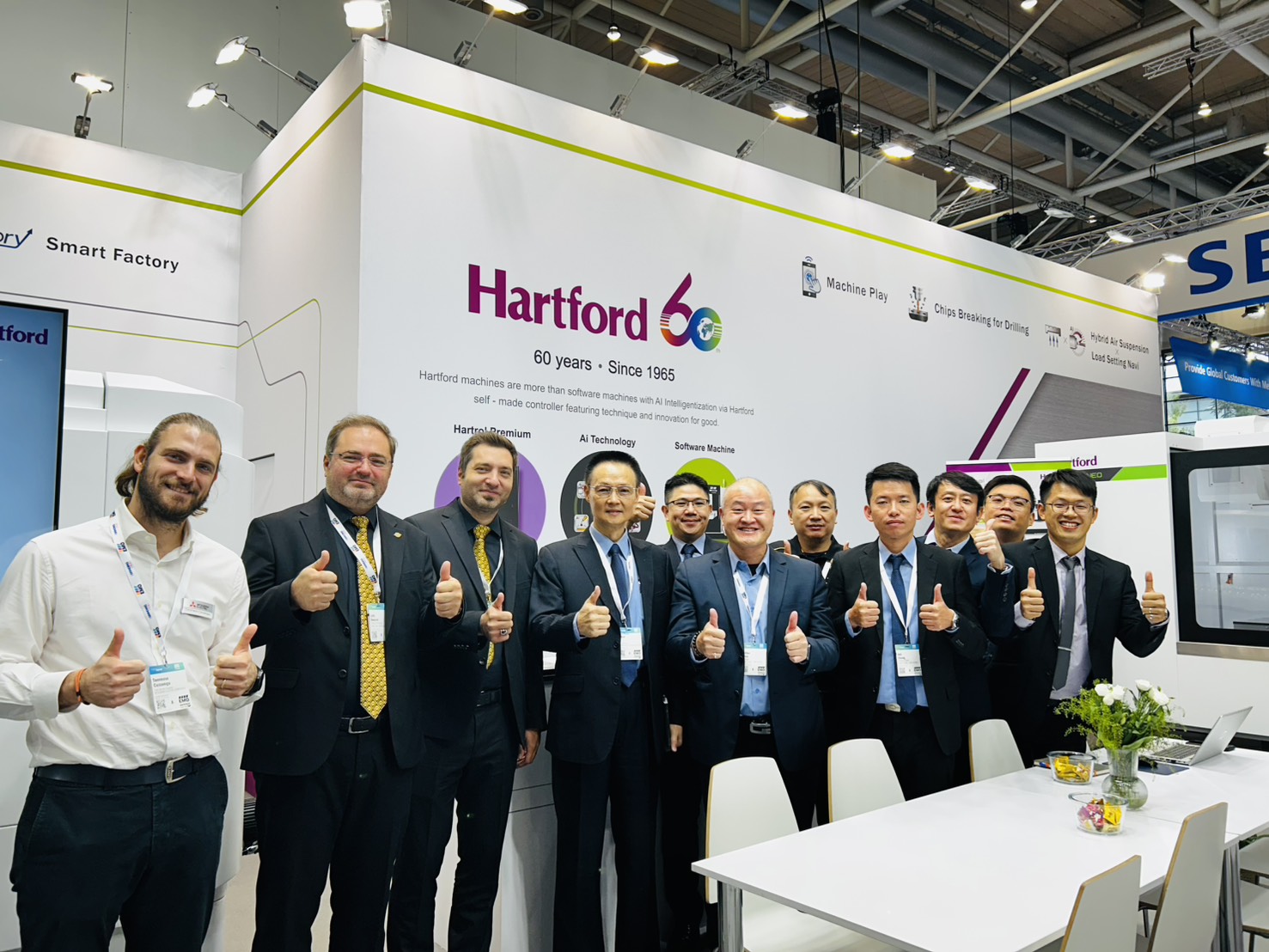

However, the wheels of time never stop turning. When the leadership baton passed to the third-generation Executive Director, Chen Chih-Chieh, he faced intense competition from China and Japan, as well as the sweeping global wave of smart manufacturing transformation. Yet instead of sticking to a conservative, preservation-focused strategy, he chose the courageous path of transformation.

With the support of the Industrial Development Administration and the Precision Machinery Research & Development Center, Victor Taichung implemented AI real-time monitoring and smart energy management systems. The transformation results were remarkable: maintenance costs fell by 5–10%, equipment unit prices rose by more than 10%, and machining precision improved dramatically.

This case proves that when traditional craftsmanship meets AI, it is not replaced — it is upgraded. The Industrial Development Administration will continue to stand alongside Taiwan’s industries, using technology to deepen craftsmanship and transformation to open the future.

Source :