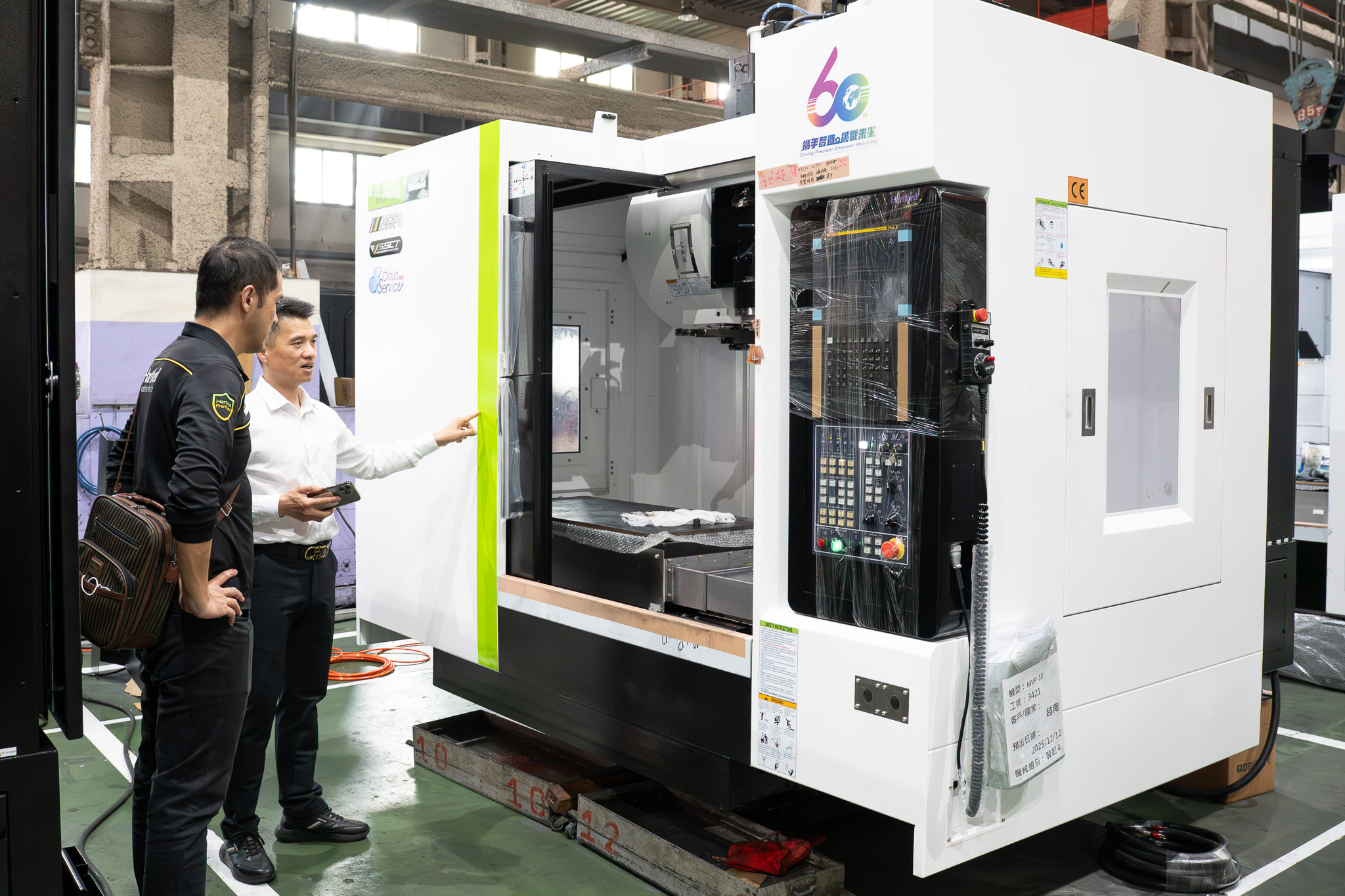

MVP-13 High-Precision Machining Center Earns Customer Recognition Once Again

We were honored to welcome General Manager Yeh and his team from Qing Hong Machinery (H.K.) Co. for a factory visit and machine acceptance of Hartford’s latest MVP-13 high-precision vertical machining center. During the full verification and machining test, the MVP-13 demonstrated outstanding cutting capability, exceptional structural rigidity, and long-term accuracy stability—earning strong recognition from the customer.

Five Core Advantages of the MVP-13

The MVP series is the result of Hartford’s decades of R&D strength, designed to deliver high precision, high efficiency, and long-term machining stability.

This acceptance test not only showcased the machine’s performance but also further strengthened technical exchange and future cooperation between both companies.

During the evaluation, the customer gave highly positive feedback on the MVP-13’s structural design, machining quality, user interface, and operational convenience.

1. High-Rigidity One-Piece Structure Ensures Stable Heavy-Duty Performance

The MVP-13 adopts a high-rigidity casting and one-piece structural design, enabling the machine to maintain excellent stability even under heavy cutting and high-feed conditions. Its superior vibration-damping capability minimizes machining-induced vibration, ensuring more consistent dimensional accuracy and improved surface finish.

2. Large Travel and High-Load Table for Diverse Applications

To meet the needs of mold, aerospace, precision parts, and other industries, the MVP-13 is equipped with a high-load table and large machining envelope. This allows flexible multi-fixture or multi-workpiece setups, enhancing shop-floor efficiency and production flexibility.

3. High-Torque Spindle Delivers Both Speed and Power

The MVP-13 features a high-torque spindle that provides strong cutting capability during roughing while maintaining excellent stability and smooth surfaces during finishing operations. With optimized spindle thermal control and dynamic characteristics, the machine delivers exceptional long-term durability and reliability.

4. Exceptional Long-Term Accuracy Stability for High-Precision Manufacturing

In extended continuous machining tests, the MVP-13 maintained micron-level accuracy, demonstrating not only its robust structural rigidity but also Hartford’s strength in thermal compensation and precision-control technologies. This makes the MVP-13 particularly suitable for high-precision applications such as molds, jigs, medical components, and other industries requiring stringent dimensional tolerance.

5. Smart and User-Friendly Interface Improves Operational Efficiency

The MVP-13 incorporates an intuitive intelligent interface with multiple assistive functions that significantly shorten operator learning time and setup procedures. After hands-on operation, the customer noted that the system is easy to understand, responsive, and highly beneficial for improving workflow efficiency and on-site management.