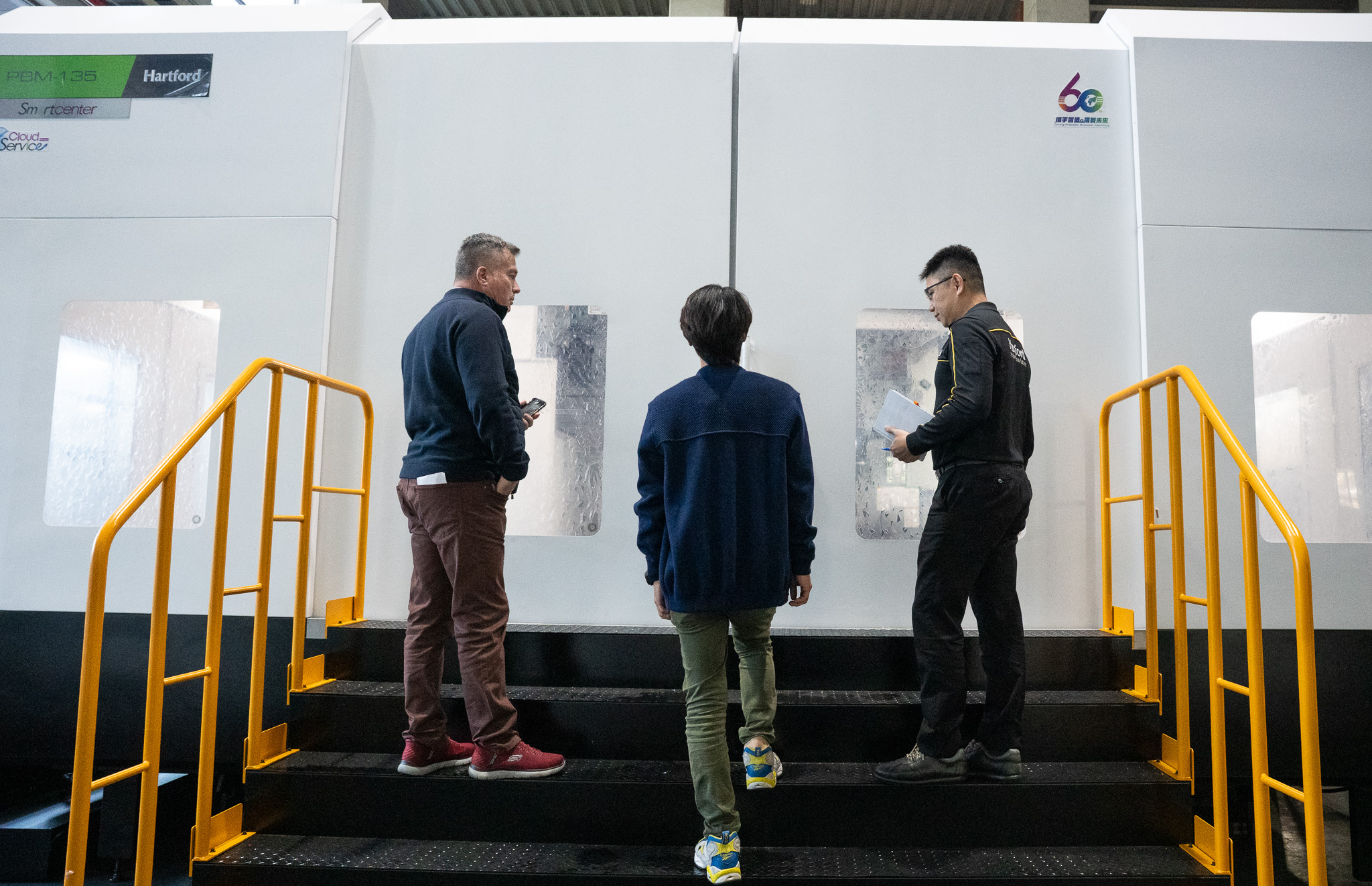

A Swedish customer recently visited Hartford for a comprehensive technical and market exchange, engaging in detailed discussions on equipment applications, industry requirements, and product characteristics. The visit enhanced mutual understanding on multiple technical fronts and reflected the high level of attention that the Nordic manufacturing sector places on precision machining equipment.

The itinerary included guided tours of Hartford’s horizontal gantry machining equipment and Hartford Motorcycle, offering an overview of machine structure, performance features, and engineering concepts. The horizontal gantry series is known for its high rigidity, stable cutting performance, and capability for large workpiece machining, serving industries such as aerospace, mold manufacturing, and energy equipment. Through on-site demonstrations, the visiting customer gained a clearer understanding of the series’ dynamic accuracy, thermal stability, and structural configuration.

During the visit to Hartford Motorcycle, discussions covered engineering workflows, component machining processes, quality verification methods, and production-line planning. Sweden’s industrial environment is characterized by high expectations for equipment consistency, operational stability, and long-term precision. The exchange provided the customer with a comprehensive view of Hartford’s manufacturing capabilities, quality-control logic, and engineering depth.

Additional technical topics included large workpiece machining strategies, automation adoption in Nordic factories, material-specific machining settings, thermal displacement control approaches, structural rigidity considerations, and torque requirements for heavy cutting. Hartford’s engineering team offered detailed explanations across multiple domains—accuracy control, dynamic motion behavior, spindle performance, and practical application cases—enabling both sides to obtain solid, technical-level information.

The customer also shared insights into the Swedish industrial landscape, describing procurement practices, machining habits, expectations for equipment durability, preferred maintenance intervals, and production-line requirements for high-efficiency machining. These observations contributed to a more refined understanding of the Nordic market, particularly regarding equipment configuration logic and operational methods.

The visit further explored industry-wide themes relevant to global manufacturing, including high-efficiency cutting technology, precision management strategies, thermal compensation mechanisms, structural optimization methods, and the integration of multi-functional machine models. Through cross-border knowledge exchange, both sides gained complementary insights that enriched the technical depth of the conversation.

The visit proceeded in an organized, professional, and technically focused manner. The Swedish customer showed strong interest in Hartford’s production processes, factory environment, engineering capabilities, and machine design, raising numerous technical inquiries that supported a deeper dialogue. The exchange strengthened mutual understanding in key areas such as market needs, product characteristics, and industry trends, building a more robust foundation for ongoing communication.

Through this visit, both parties achieved greater alignment in technical comprehension, application logic, and market structure awareness. The information shared throughout the discussions provided valuable reference points for understanding international customer requirements and highlighted Hartford’s commitment to engineering excellence and high-precision manufacturing.