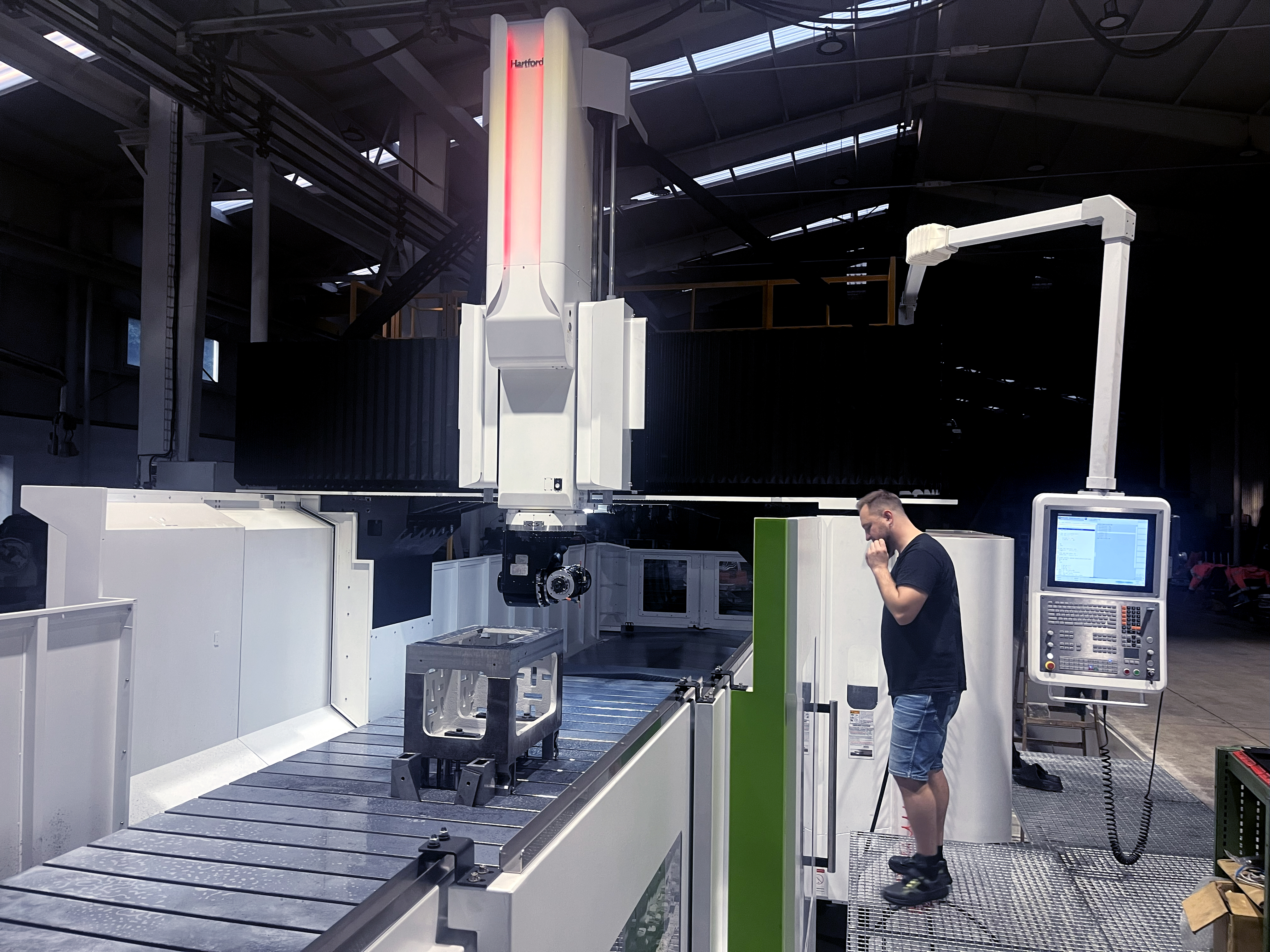

Hartford Service Team Travels to the Czech Republic to Resolve HSA-628EA Operating Issues — Demonstrating Strong Global After-Sales Support Capability

On-Site Support in the Czech Republic — Identifying the Root Cause and Restoring Productivity

The customer had reported difficulties in operating the HSA-628EA during daily machining, including issues related to five-axis settings, machining parameters, toolpath configuration, workpiece positioning, and control functions. To ensure the customer could resume stable production as quickly as possible, Hartford immediately activated its global service mechanism and arranged an overseas assignment for a senior service specialist.

Upon arriving at the Czech factory, the Hartford engineer conducted a complete machine inspection and worked directly with the customer's production workflow. This included reviewing control settings, machining programs, tooling conditions, and environmental factors. By analyzing each issue step by step, the engineer identified the root causes and provided the most effective corrective solutions. After several rounds of testing, adjustments, and machining verification, the machine’s stability, cutting quality, and machining efficiency improved significantly. The customer also gained a much clearer understanding of the correct operating procedures of the HSA-628EA.

The customer expressed strong appreciation, stating: “Hartford responds quickly and provides solutions that truly work on the shop floor. Their level of expertise makes them a partner we can confidently rely on.”

Comprehensive Training and Demonstration — Ensuring Full Mastery of the HSA-628EA

To further enhance the customer’s operational capability, Hartford provided a full set of on-site training and optimization support, including:

- Five-axis machine setup, rotation center explanation, and basic calibration

- Toolpath demonstration and interference avoidance

- Tool selection and cutting parameter optimization

- Controller operation and interface usage

- Machining improvement for actual production parts

- Daily maintenance guidelines for sustained long-term performance

The training emphasized both the structural characteristics of five-axis machining and the logical understanding behind each operation. Rather than memorizing steps, the customer learned the “why” behind each procedure, enabling them to apply knowledge independently to future machining tasks. Following the training, the customer team demonstrated improved confidence and efficiency in operating the HSA-628EA.

Intelligent After-Sales Tools Supporting the Process — Faster Diagnosis, More Accurate Solutions

Although this assignment required on-site service, Hartford’s intelligent cloud-based after-sales system also played an important role in streamlining the service process. Before departure, the service team accessed system data and machine status to perform initial diagnostics, allowing the on-site intervention to be more targeted and efficient.

Hartford’s smart service system includes:

- Real-time monitoring of machine status, alarms, machining progress, and the on-machine camera

- User Connect, enabling remote connection to the machine for diagnosis, software updates, and troubleshooting

- FAQ App / QR code, offering instant access to operating knowledge and maintenance guides

- Online service support, allowing customers to report issues anytime for fast case handling

- These tools ensure that even overseas customers receive timely and reliable technical assistance, minimizing downtime and improving the overall service experience.

Hartford’s Global Service Commitment — More Than Maintenance, A Long-Term Technical Partnership

This service mission in the Czech Republic once again demonstrates Hartford’s dedication to providing not only high-quality machines but also complete machining solutions. Whether the need is:

- On-site technical support

- Remote diagnostics

- Process optimization

- Operator training

- Quality improvement guidance

Hartford’s service goal remains the same — to ensure every Hartford machine delivers optimal performance and every customer receives dependable, long-term support.

With a global service network spanning more than 40 countries and continuous development of intelligent service tools, Hartford is committed to offering faster, smarter, and more comprehensive support to manufacturing customers worldwide.